- SME Sustainability Hub

- Kickstart Your Journey

- Case Studies

- XCEL Industrial Supplies

XCEL Industrial Supplies: Leading in product innovation and energy efficiency

With strong leadership and a passion for sustainability, XCEL Industrial Supplies (XCEL) has transformed their organisation to provide products and services that not only reduce their waste and carbon footprint, but also help their customers reach their sustainability goals in the process.

XCEL is a leading manufacturer of pallets and other packaging products, serving customers in the oil & gas, F&B, electronics, medical and logistics industries. Known for its strong commitment to sustainability, XCEL embarked on a multi-year journey that saw the company spearheading new business models to recycle and repurpose their wooden products, transforming their waste data management processes, and implementing cost-saving energy practices.

XCEL’s sustainability journey showcases the following key lessons:

- Long-term commitment and persistence is important to build trust for sustainability efforts with customers

- Data collection and management are key enablers for companies to track efforts and offer sustainability insights to customers

- More energy-efficient technologies have the potential to significantly reduce business costs, benefitting both business and the environment

Sustainability as a solution can build business resilience

Cognisant of the amount of waste generated from the pallets, XCEL had a considerable head start in exploring circular economy solutions. XCEL’s Managing Director, Jean Goh, shared: “In the early 2000s, one of our young engineers challenged our model as being a contributor to global warming. This deeply motivated me to improve on our business practices, and to strive for XCEL to become a champion for change within the pallet and packaging industry.”

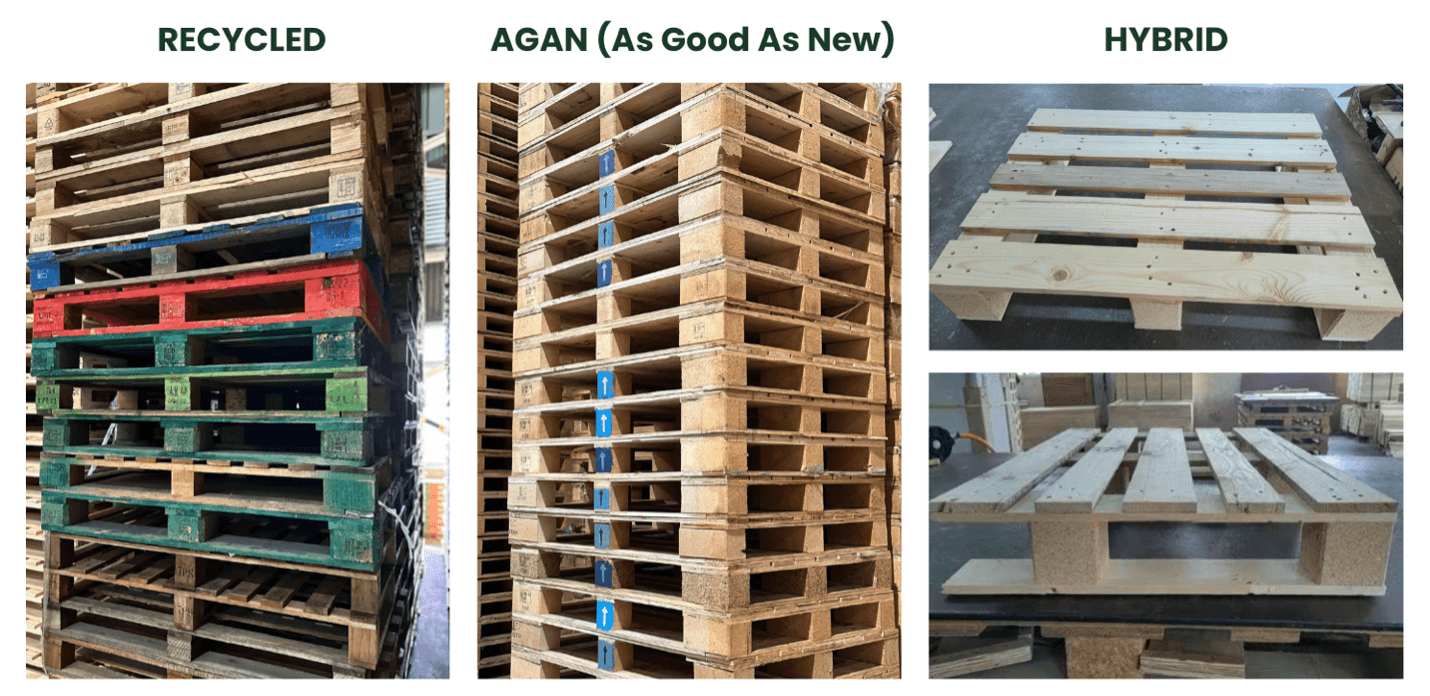

XCEL started researching different ways of repurposing the used wooden pallets under their pallet recycling programme. Despite the innovative solution, less than 10% of XCEL's customers were interested in adopting this new product due to apprehension regarding the quality of the recycled wooden pallets.

However, the Covid-19 pandemic prompted a rethink amongst local companies. The disruption of international trade led to a cut in supply and a sharp increase in the cost of raw materials, prompting XCEL’s customers to reconsider XCEL’s recycled and repurposed wooden pallets.

Types of pallets offered under XCEL’s pallet recycling programme (Image: XCEL)

To reassure their customers, XCEL conducted an extensive research and development (R&D) process, involving stress and durability testing, to demonstrate that there was no drop in the performance of the recycled and repurposed pallets. XCEL’s General Manager, John Goh, also met with customers to share how the recycled pallets were made and explained their lab-tested quality and cost-saving benefits. Understanding the recycling process and the level of quality checks have helped to overcome the customers’ initial apprehension.

Dismantling and recycling process of wooden pallets (Image: XCEL)

XCEL’s persistence and outreach efforts convinced more than 50% of their customers in accepting the use of recycled pallets, creating a more resilient business model while doing good for the environment.

Benefits of adopting recycled pallets

- Saved up to 10-30% of the costs (e.g. operational cost, material cost) when purchasing recycled pallets

- Reduced waste management costs for disposing of used pallets

- Reduced approximately 500 tonnes of wood waste per year, equivalent to over 6,900 trees

Building internal capabilities to serve customers’ sustainability needs

Besides developing its pallet recycling and repurposing programme, XCEL has been improving its data collection process to support customers in meeting regulatory requirements. An example of this is the Mandatory Packaging Reporting (MPR) Scheme introduced by the National Environment Agency (NEA) in 2020, which requires companies to disclose their packaging data and 3R plans. As a packaging supplier, XCEL recognised this as an opportunity to support their customers' reporting.

To provide their customers with organised data for regulatory reporting, XCEL had to first improve on its own data collection and management processes. They enrolled their employees into courses to strengthen the teams’ data collection skills. XCEL is exploring the digitalisation of its Rework Feedback Form (RFF) by equipping teams with electronic tablets to efficiently track relevant waste data, which will provide the backbone for creating the finalised report for customers’ use. With these foundational steps in place, XCEL was able to collaborate closely with their customers to offer data-driven insights on waste reduction targets and areas for improvement.

Proactively adopting energy-efficient sustainability solutions

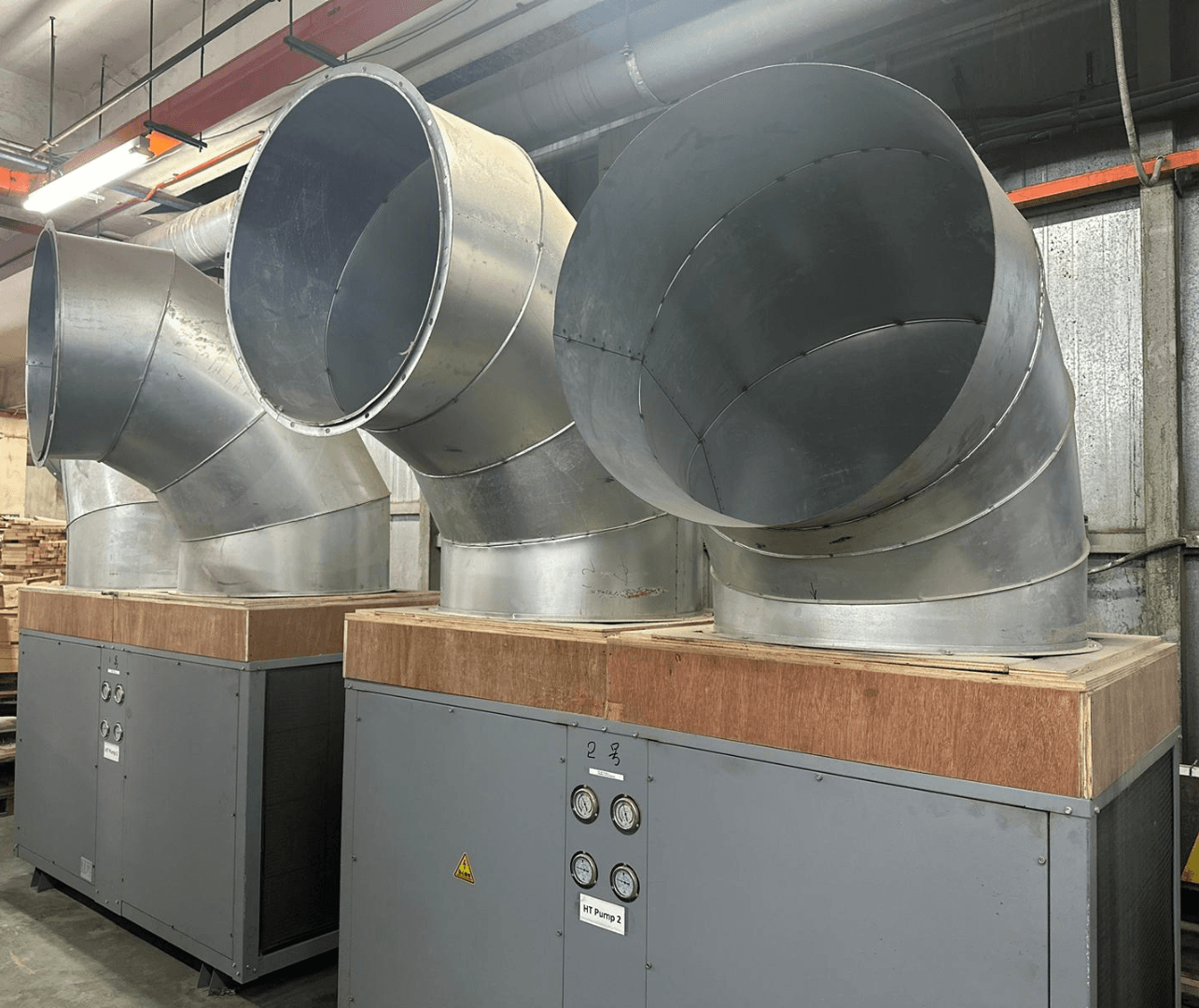

Faced with rising energy prices and pass-through of Singapore’s carbon tax, XCEL also sought to reduce their energy consumption. They started by reviewing energy consumption in their business operations and identified their heat treatment facility as the most energy-intensive process. After assessing possible options, XCEL decided to retrofit them using heat pumps as a more energy-efficient alternative.

Heat pump system installed in XCEL’s heat treatment units (Image: XCEL)

While the initial investment of approximately $60,000 to $80,000 was high, utilising a more energy-efficient technology has paid off as XCEL managed to achieve a return on investment (ROI) within just six months, realising a 40% reduction in its electricity costs. In addition, the solution has not only cut down XCEL’s energy consumption but also provided cool air, making the workplace more comfortable for their workers.

Recognising the benefits of heat pump technologies, XCEL also partnered with the Singapore Timber Association to promote its use within the sector.

Embracing their role as stewards for a sustainable future

From recycling products, establishing a robust data management system and installing energy-efficient solutions, XCEL has fully embraced its sustainability transformation. Recognising that sustainability is a journey which involves collaboration between all stakeholders, Goh shared that, “It’s important to be consistent in your sustainability efforts. In our journey, a lot of our important customers have grown together with us. But the most important message that I want to share is, continue and never give up.”